For those who are ahead of their time there must be a desperate frustration, often a deep depression, as the world around them fails to see the brilliance of their creation. In the late ’70s Honda moved one such man, engineer Shoichiro Irimajiri, from the head of F1 engine development to the motorcycle division and two of his creations were the CX500 and the CBX1000. The ugly commuter bike sold like hotcakes, while the revolutionary six ended up being given away to trade schools. But oh how times have changed; so when a man with an enviable collection of cars and bikes approached China’s Mandrill Garage wanting only the most desirable of builds, they quickly selected the singing six-cylinder Honda CBX.

“This project’s client is a senior car media person who has a lot of motorcycles, various brands, and types. So we believe his custom bike must be special, so we selected the CBX,” Mandrill’s Luo Hao told us. Then with the client, the team discussed a number of directions and styles in which they could take the build, but ultimately the decision was made to create a classic cafe racer with the engine to look like it could be taken from a race bike. While a considerable diet was also on the menu with the factory machine weighing nearly 600lbs wet.

But making those decisions was the easy part, importing motorcycles into China is not an easy task and is even more difficult with ‘luxury’ classed vehicles. So after all the right paperwork was completed a 1981 CBX-B, the sport-touring model, with Pro-Link monoshock rear suspension, air-adjustable 39mm front forks, a fairing and panniers was found in excellent condition and put on a ship for the journey to Beijing. But all those extras would be tossed aside “For me the CBX soul is the inline 6 engine, so I only kept the engine and main frame,” Luo Hao describes.

With the bike in their hands the Mandrill Garage team set to work on the chassis, checking the main frame for cracks and weld integrity, before smoothing things out. Then the subframe was cut back, to remove the section that had been re-inforced for the heavy panniers and a new slimline unit welded into place. The heavy factory swingarm was ditched and a lightweight alloy unit from a Kawasaki ZRX was selected that would allow the bike to be converted back to a twin shock setup.

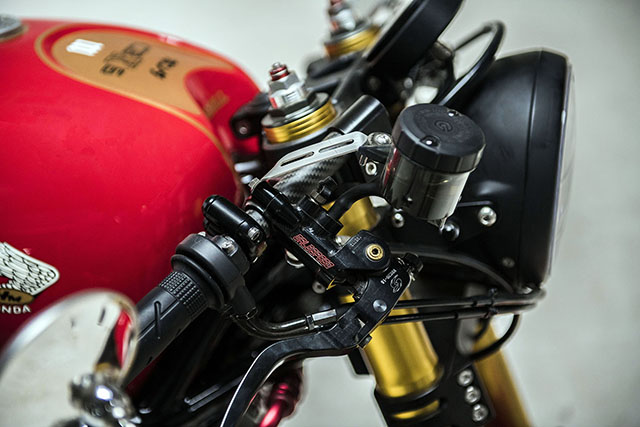

With the new mounts welded in and all new bolts and bearings added, the frame and arm were given a coat of gloss black. Before the high-end only suspension using the best parts available was pieced together, the new rear shocks were custom ordered to suit the project from Gears Racing. To match the front end is also given the full treatment with a custom set of machined triple clamps securing a set of Showa USD adjustable forks. The braking too was brought into the 21st century, radial-mounted Brembo brakes clamping 320mm floating discs up front and a new disc conversion for the rear.

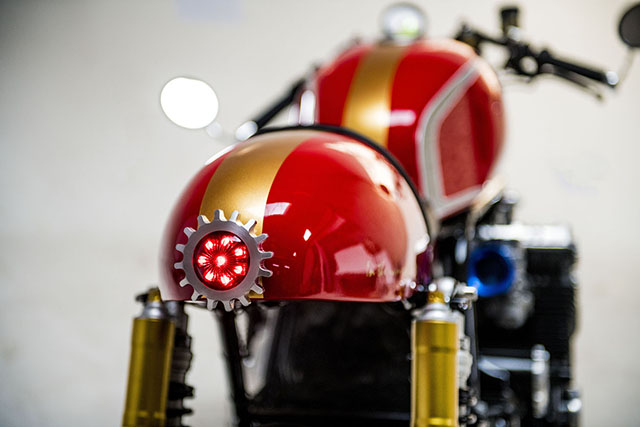

Not being a fan of the ’80s “square” look of the bike Luo Hao instructed his team that they’d be going for smoother lines. So all the bodywork was removed and the gorgeous flowing designs of the new tank and cafe-esque tail section were hand formed by the crew from lightweight aluminium. With the removal of the factory steel and so many other components, this helps bring the overall weight down considerably. “The colour uses Honda’s classic red and gold, and the silver on the fuel tank is from an Oberdan Bezzi design, and here I must say ‘Bezzi, your design gave me a lot of inspiration’,” Luo smiles.

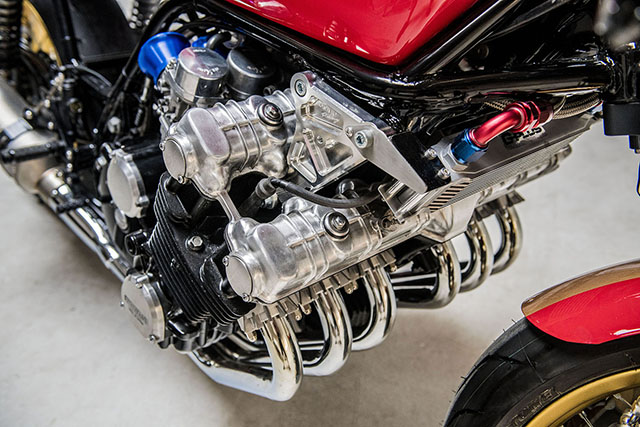

Now with everyone at Mandrill keen to get their hands dirty, they got stuck into the glorious six-cylinder engine securing it in place with CNC machined Over Racing mounts. For reliabilities sake the engine was given a full rebuild and a new oil-cooler with race-style Speedflow fittings. The exhaust underwent multiple incarnations before the team settled on a pair of 3-1 headers that vent back to modern mufflers on each side. The blue velocity stacks have been chosen to give the bike a look straight from the classic racing paddock before the bank of six Keihin carbs were meticulously tuned.

Having put some much effort into the performance of the bike, the accessories are kept to a bare minimum to keep the weight low. All of which is made much easier with a total re-wire of the bike and use of an m-unit and Motogadget accessories. The rearsets are machined aluminium with the carbon fibre clip-ons barely registering on the scale. The final change sums up the entire build; with the ultralight rims in a 17in diameter so modern Bridgestone performance rubber could be fitted, the rear end a 180section that helps get all that torque to the ground. The bike has no name, it doesn’t need one, the sound of an F1 starting grid in the distance gives it away and completes a remarkable build that would have Shoichiro Irimajiri smiling!